The efficient and accurate manufacturing of corrugated metal plates or panels is the primary focus of the design and use of the corrugated plate roll forming machine, a crucial piece of machinery in the area of contemporary metal processing. The apparatus converts metal coils into wavy sheets using a particular rolling technique to satisfy the demands of various industries for metal plates with unique shapes.

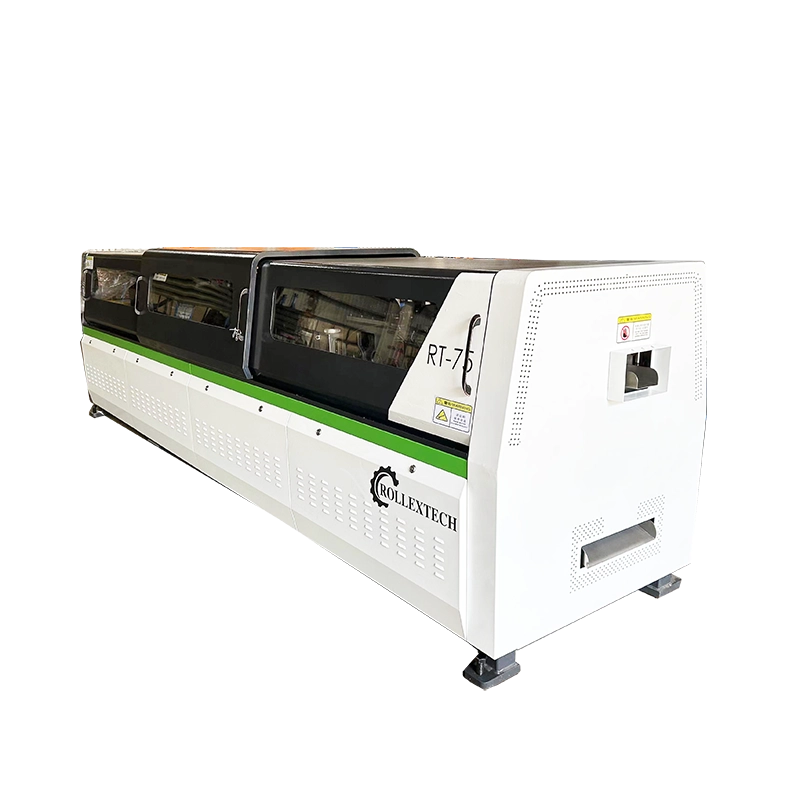

Machine Technical Parameter

| No. | Item | Parameter |

| 1 | Machine size | 7500*1780*1400mm |

| 2 | Machine weight | 5500kg |

| 3 | Machine power | 5.5kw |

| 4 | Hydraulic engine | 2.2kw |

| 5 | Roll speed | 16-20m/min |

| 6 | Roll stations | 15-20 |

| 7 | Roller material | 45#Steel |

| 8 | Effective width | customized |

| 9 | Feeding width | 914/1000/1219mm |

| 10 | Voltage | 380V 50Hz 3PH/Customized |

| 11 | Material thickness | 0.35-0.65mm/Customized |

| 12 | Control System | Schneider/Delta/Customized |

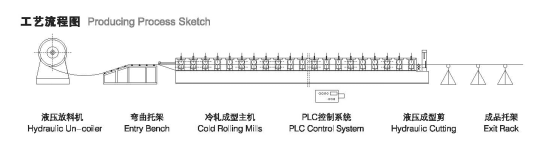

Work Flow

Decoiler→Feeding Guide Device→Pre-Cutting Device→Roll Forming System→Hydraulic Post Cutting Device→Exit Rack

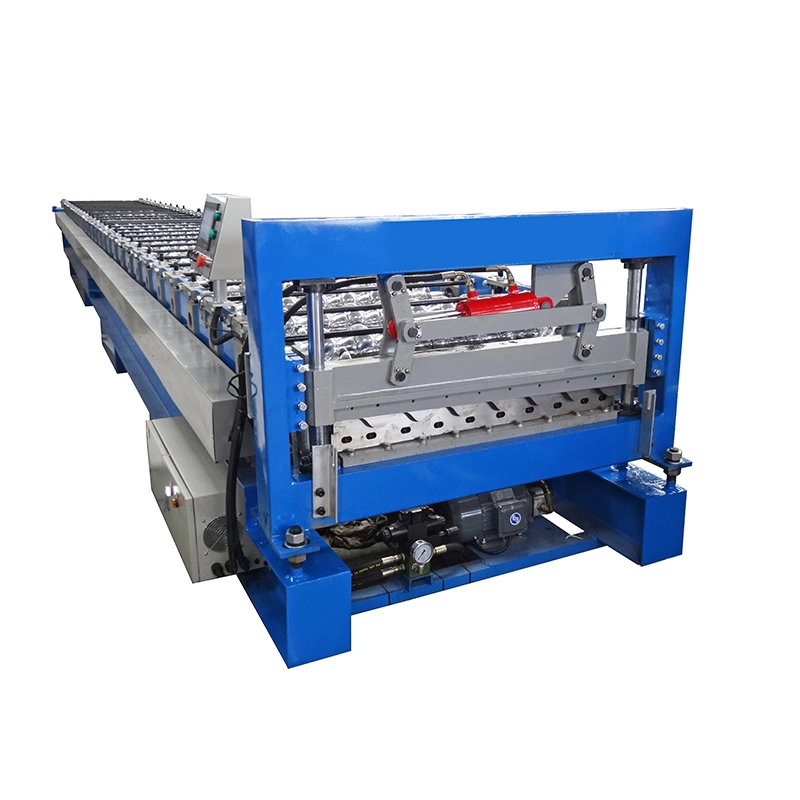

Operational concept

The corrugated plate roll forming machine operates on a somewhat simple yet effective premise. When the machine is in operating condition, a roll of metal coil is inserted into the feed port, the machine is turned on, and the metal coil is fed through a sequence of properly positioned rollers. The pre-established corrugated template is followed in the arrangement of these rollers. The rollers’ motion will cause the metal coil to progressively distort as it goes through, eventually taking the form of a wavy corrugated plate.

Choosing Metal Sheets

Cold-rolled steel sheets are often used as the raw material for corrugated plates. It is possible to treat various metal sheets based on the requirements and usage environment. Typical materials include of galvanized steel sheets, organic coated steel sheets (also known as color-coated steel sheets), anti-corrosion steel sheets (covered with layers of asbestos asphalt), etc. These materials may be surface-treated to provide a variety of looks and performances in addition to their high strength and durability.

Features of sheets with corrugations

Corrugated metal plates are unique in that they possess a number of noteworthy qualities. In order for the corrugated plates to lower the building’s total weight while maintaining strength, they must first have a low unit weight and a high strength. Second, the corrugated plates can withstand the damage caused by earthquakes and other natural calamities because of their strong seismic resistance. Corrugated plates are also quick to make and have a lovely look, which is why they are utilized extensively in a variety of industries including agriculture, transportation, and construction.

Application

Our corrugation roll forming machines allow for high-speed manufacturing, precision forming, and bespoke corrugation patterns to fulfill a variety of design and application needs.

Corrugated panels are also quite versatile in interior design and can be used in home, office, and commercial settings. Straight corrugated boards are ideal for residential projects because they are less monotonous than vast white walls and are easier to combine with the varied textures on them.

Corrugated panels can be utilized to partition workplace spaces, and diffused light can create a sense of spaciousness. At the same time, it generates a sense of difference by contrast with other materials’ walls, allowing each room to have its own visual identity.