We have extensive expertise in the roll forming machine industry as a competent producer of specialized roll forming machines. We are aware that every machine brings with it the particular requirements and demands of our clients. As a result, we provide OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services to guarantee that our roll forming machines can satisfy your unique requirements.

A fully tailored solution is what you will get if you choose our ODM service. Our expert staff will collaborate directly with you to provide you technical help and professional guidance on everything from design and material selection to manufacturing and testing. We make sure every roll forming equipment lives up to your expectations and operates efficiently when put to use.

Custom Roll Forming Machine

- We may also provide you OEM services if you already have your own design and brand. In accordance with your specifications, we will build roll forming machines that match the look and performance standards of your brand. To make sure that every machine can demonstrate the power and worth of your brand, we focus on quality and details.

- We have state-of-the-art manufacturing equipment and a skilled R&D staff. In order to guarantee that the performance, accuracy, and stability of our roll forming machines dominate the industry, we place a strong emphasis on technical innovation and quality improvement. We guarantee that every machine achieves high quality standards by closely adhering to international standards and client specifications while producing and testing.

- We provide thorough pre-, sales, and post-purchase services. During the pre-sales phase, we offer expert guidance and cost-effective solutions tailored to your requirements; during the sales phase, we monitor production progress and product quality; and during the post-sales phase, we offer prompt repair and maintenance services to guarantee your machine remains in optimal working order.

Feature of customized roll forming machine

Customized roll forming machine, also known as cold bending, rolling, roll bending or roller forming machine, is a kind of equipment that uses continuous roller bending method to process metal sheets or strips into various open, closed, wide and deformed section metal profiles. Its core technology lies in customized design and efficient manufacturing, which can meet the specific needs of customers and realize efficient and automated production.

Customized roll forming machine has a wide range of applications, including metal processing, construction, chemical and power industries. In the field of metal processing, it can be used to produce large metal components such as steel plates, pipes and cylinders. In the field of construction, it can be used to produce building materials such as cold rolled coils, color steel plates and color steel sandwich panels. In the chemical and power industries, it can be used to manufacture high-strength, high-pressure, corrosion-resistant metal components and parts to ensure the safety performance of equipment.

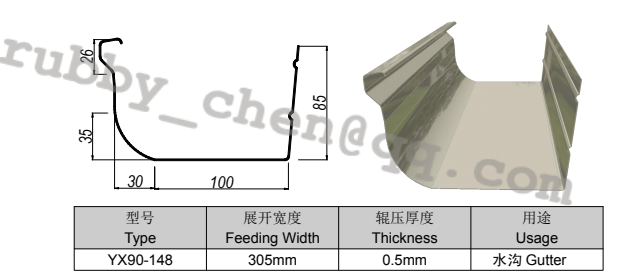

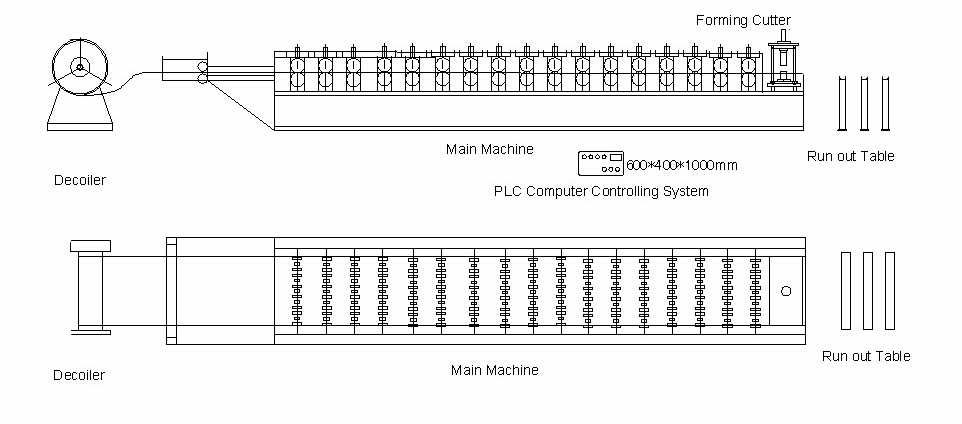

Profiles and flow chart of customized roll forming machine

Customized roll forming machines are high-end equipment designed and manufactured for specific industries and application requirements. With our rich manufacturing experience and professional technology, we are able to provide customers with a full range of customized services from design to manufacturing. This type of equipment is widely used in many fields such as material forming, metal processing, and plastics industry. It has the advantages of high forming accuracy, high production efficiency, and easy operation.

Roll Forming Machine Core Components Overview

Feed system:

The feeding system is the starting point of the roll forming machine. It is responsible for transporting the raw material to the working area in a stable and continuous manner to ensure the smoothness of the subsequent processing.

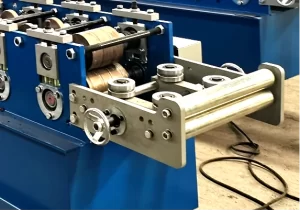

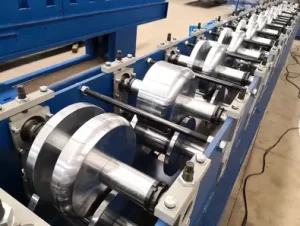

Machine rollers:

Rollers are one of the core components of a roll forming machine, they continuously roll and shape the raw material through precise rotation and pressure adjustment. Our rollers are made of high-strength materials to ensure stable performance under high workload conditions.

Forming Tools:

Forming tools are key components in the realization of material forming. Designed and manufactured to meet specific molding needs, they transform raw materials into compliant finished products through precise cutting and shaping. Our molding tools undergo rigorous quality testing to ensure that every process achieves the desired results.

PLC control system (two types available):

PLC control system is the intelligent brain of roll forming machine, which is responsible for monitoring and controlling the whole machine operation. We provide two types of PLC control system for customers to choose, one focuses on easy operation and the other emphasizes on advanced functions and flexibility. Whichever type you choose, we can ensure that the system is stable and reliable to meet your production needs.

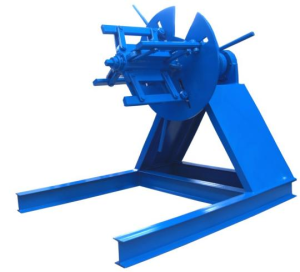

Uncoiler (two types available):

Manual Uncoiler: For small or low-frequency production scenarios. The manual operation is simple and intuitive, and can be used for basic unwinding needs.

Hydraulic unwinders: for large-scale or high-frequency production scenarios. Hydraulic unwinders provide strong unwinding power through the hydraulic system, ensuring that the raw material remains stable and smooth during the unwinding process, improving production efficiency and product quality.

Our workshop

Our workshop has a spacious manufacturing space with an area of thousands of square meters, which provides a good environment for the production of roll forming machines. The internal layout of the workshop is reasonable, divided into raw material area, machining area, assembly area, debugging area and finished product storage area, which ensures the smooth production process. We pay attention to the environment and safety of the workshop, equipped with perfect fire-fighting facilities and safety monitoring system. At the same time, we have also set up a strict production safety system to ensure the personal safety of employees and the normal operation of equipment.

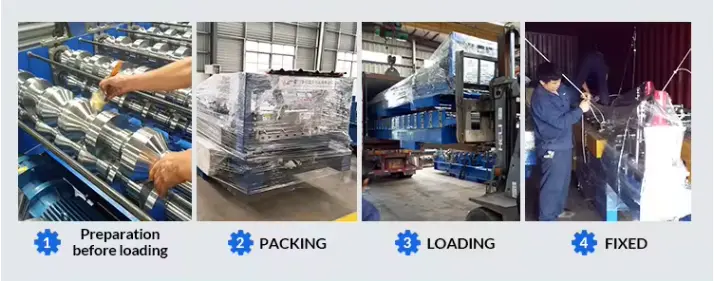

Production process

- Raw material preparation: In the raw material area, we prepare suitable raw materials such as steel, aluminum, etc. according to the order requirements.

- Processing and manufacturing: In the processing area, advanced processing equipment is used to cut, drill, weld and other processes on the raw materials to form various parts.

- Assembly and debugging: In the assembly area, technicians assemble the various parts according to the drawings and carry out preliminary debugging to ensure that the basic functions of the machine are normal.

- Finished product debugging: In the debugging area, the assembled roll forming machine is fully tested and debugged to ensure that the various indicators of the machine meet the design requirements.

- Finished product storage: The roll forming machine that has passed the debugging will be moved to the finished product storage area, waiting for shipment or further processing.