Because of its distinct benefits, light gauge steel framing, or LGSF, is preferred in the area of contemporary building. This structure gives the construction industry fresh life by lowering the building’s total weight and increasing construction efficiency. Let’s examine the steel used in light gauge steel framing, its benefits and drawbacks, and the companies that make LGSF machinery in detail today. We should specifically bring up SKD as a reputable producer.

What steel is used for light gauge steel framing?

The primary material used in light gauge steel framing is cold-rolled thin-walled steel. Although the wall thickness of this steel is typically thinner (between 0.5 and 2.0 mm), it nonetheless offers excellent toughness and high strength. Precision machining and assembly benefit greatly from the smoother, more accurate dimensional surface that results from the cold rolling process. Furthermore, cold-rolled thin-walled steel has strong corrosion resistance and weldability, making it suitable for a variety of application scenarios.

What are the disadvantages of light gauge steel framing?

While low gauge steel framing offers several benefits, certain drawbacks are unavoidable. First, since steel has a high heat conductivity, LGSF structures may need to incorporate more thermal insulation to maintain a comfortable interior temperature. Second, light steel structure frames need further fire protection treatment to lengthen their fire resistance duration in buildings with strict fire safety regulations. Furthermore, even if the structure as a whole is lightweight because of the relatively high density of steel, care should still be taken to reduce costs and maximize efficiency during installation and transportation.

What are the advantages of light steel structure frames?

Light steel building frames have clear benefits. First off, because of its strong strength and light weight, the building’s deadweight can be significantly decreased, foundation treatment costs can be decreased, and the building’s seismic performance may be enhanced. Second, LGSF can greatly reduce the building duration and increase construction efficiency due to its quick construction pace and little on-site labor. Additionally, it is simple to produce standardized, serialized, and industrialized manufacturing using this structural system, which helps to save construction costs and improve building quality. Lastly, light steel structure frames are consistent with the idea of sustainable development and have excellent environmental performance and great recyclability.

Who is the manufacturer of LGSF machines?

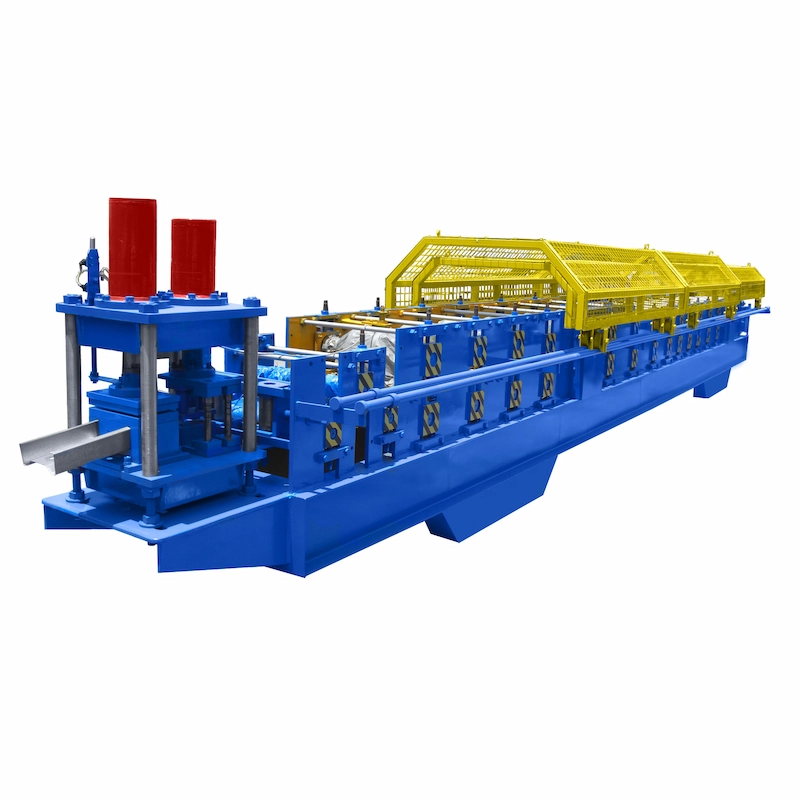

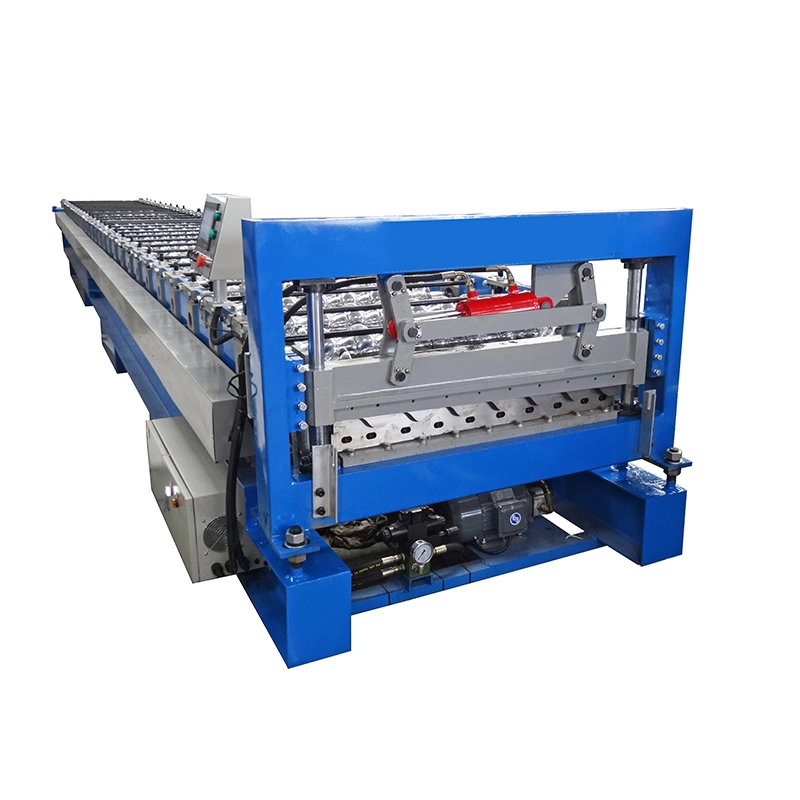

Being a seasoned manufacturer, SKD has a solid technological base and strong technical foundation in the area of producing LGSF machines. SKD’s high-precision, high-efficiency, and high-stability LGSF machines are well-known for offering robust assistance to the construction sector.

Conclusion

The construction industry is undergoing a progressive transformation thanks to light steel structure frames and the machinery that support them, known as LGSF machines. Their distinct advantages have helped them gain market prominence, and they are always encouraging innovation and growth in the construction sector. Selecting top-notch LGSF equipment and supplies will be crucial for investors and builders to accomplish sustainable, eco-friendly, and productive building.